Caps & Closures

Renuka caps and closures are essential components made with the injection moulding process for use in packaging, sealing & preserving containers & the contents within. They come in a variety of shapes, sizes & materials to suit & customise according to different end-usability & industries. They are widely used in industries such as food and beverages, pharmaceuticals, cosmetics, personal care, household products, and more.

Products

Premium Luxury Perfume Closures

Improved aesthetic of the cap boosted the sales.

Assembled Products With Multiple Parts

Specialized in manufacturing and assembling of

multiple part Caps for premium category. These

high-precision products are made for both good

aesthetics and to prevent piracy of product.

Stand-up Caps

Stand Up Caps are used with laminated tubes to meet

the basic function of protecting the product from

leakages and providing good aesthetics.

Mono and Bi-colour Flip-top Caps

Our flip-top closures are used for products like shampoo, lotion, and

conditioners. The Bi and tri-Colour is to enhance the marketability of the

product and also protects against piracy.

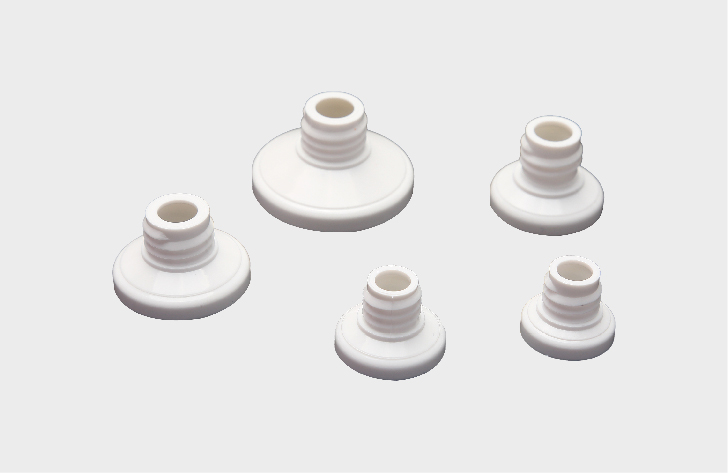

Conical Caps

Conical Caps are also used with laminated tubes and provide

variety while serving the same purpose as the Stand Up Caps.

Shoulders

Our moulded shoulder plastics used in co-extruded laminated

tubes ensure perfect dispensing of the product or cream.

These are most commonly used for tooth paste tubes, facial

creams, ointments, etc.

Caps With Hot Foil Stamping

Hot Foil Stamping gives our precision moulded caps an

ultra-premium look that ooze class on the shelf. We have the

capability to offer hot foiling as an option to our customers.

The fact that quality hot foiling needs the right technology and

expertise. It means that this will also aid counterfeiting control.

Caps With Wadding

If you need wads pre-fixed in the caps to facilitate induction sealing for tamper evidence and barrier

properties, we have the required technology. We can source and fix the wads using an automated process

for speed and accuracy of placement.

Assembled Components

Components which are manufactured for assembly with corresponding parts to create a functional

assembly like a dispensing pump need to be moulded with precision and also have to be assembled

skilfully. We specialise in both these aspects thereby providing customers a one-stop solution for products

requiring both moulding and assembly.